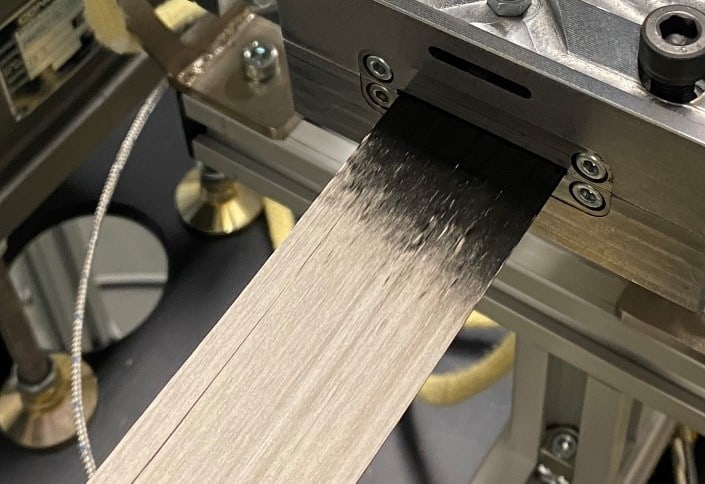

Lab scale carbon fiber reinforced thermoplastic extrusion line. The systems can be configured to work with a variety of thermoplastic materials. Tapes of up to 200mm width can be output with the system.

KYK furnaces have been the industry standard for carbonization furnaces. The highest quality carbon fiber has been produced from KYK LT/HT low temperature and high temperature furnaces for over 30 years. Production scale furnaces, as well as laboratory furnaces and pilot line furnaces for carbon fiber can be provided.

With the development of the first 3000°C furnace in the early 1980's, KYK has a rich history of developing UHT, or Ultra High Temperature Furnaces. These furnaces enable the production of high modulus carbon fibers.

These carbonization furnaces are equipped with a mesh belt to support the felt material for carbonization without applying tension.

These furnaces are designed specifically for creating gas diffusion layer (GDL), required for fuel cell production. These furnaces are used to treat carbon cloth or carbon paper.

These furnaces are designed specifically for carbonizing activated carbon fiber.

These tray pusher type furnaces are most popular in applications for heat treatment of powder materials.

According to the demands for applying a certain twist on delicate high performance fibers such as carbon fibers, Ceramic Fibers, Fiber Glass, etc., Kamitsu has developed a high speed unrolling twisting machine that does not cause damage to the fibers. The package is rotated in the cage and fiber is unrolled with uniform and constant twists. Unwinding twists are eliminated during unwinding. The number of twists can be obtained by coordinating the unrolling speed with the cage RPM (Max. 1,000 RPM). A machine with multi-built units can also be used as a doubling/twisting machine. The Kamitsu UT Twist and Detwist machine is for use with delicate fiber or yarn without damaging the yarn.

Ideal for use in carbon fiber production, this portable length and speed counter can be used to verify speed accuracy in fiber production processes or web production processes. It can also be used with any equipment with drive rollers to calibrate or set the roller speeds.

The feed-roller acts as a speed controller for any process. It has high accuracy speed control, and uses a double roller system to control the fiber speed. It is useful for laboratory type lines, pilot lines, and also scalable for large scale production lines.

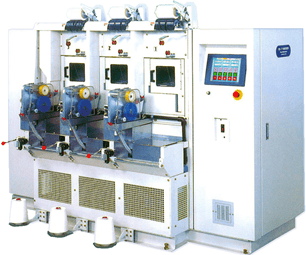

The KS-7 was developed to size various fibers, spun yarns (cotton, silk, hemp yarns, etc) as well as a variety of filament yarns to prevent fuzz, improve strength and sustain elongation properties. Linking three processes (coating/sizing, drying, and winding) into one machine dramatically improves efficiency, quality, and contributes to saving space. The KS-7 is ideal for the recent trend of manufacturing a wide variety of fabrics in small lots, at minimum time, with frequent style change.

Single tow and multiple tow spreading machine can spread a single tow of carbon fiber or multiple tow of carbon fiber. The system can also be used for other types of fiber. The fiber spreaders can be used for various applications: fiber spreading to improve impregnation of the tow, fiber spreading to make lighter materials, fiber spreading to manufacture thinner sheet materials,…etc.