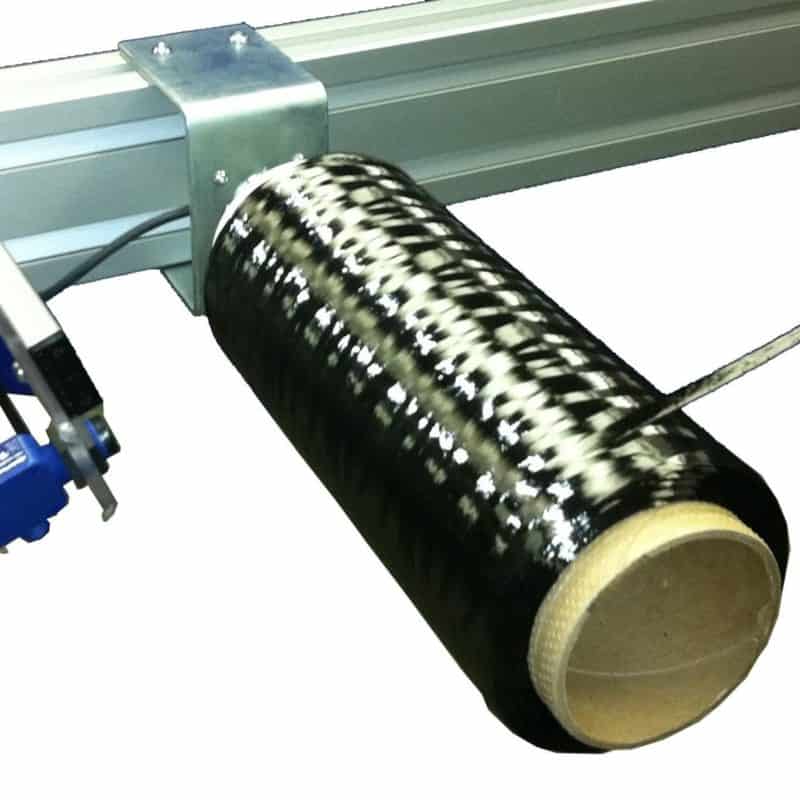

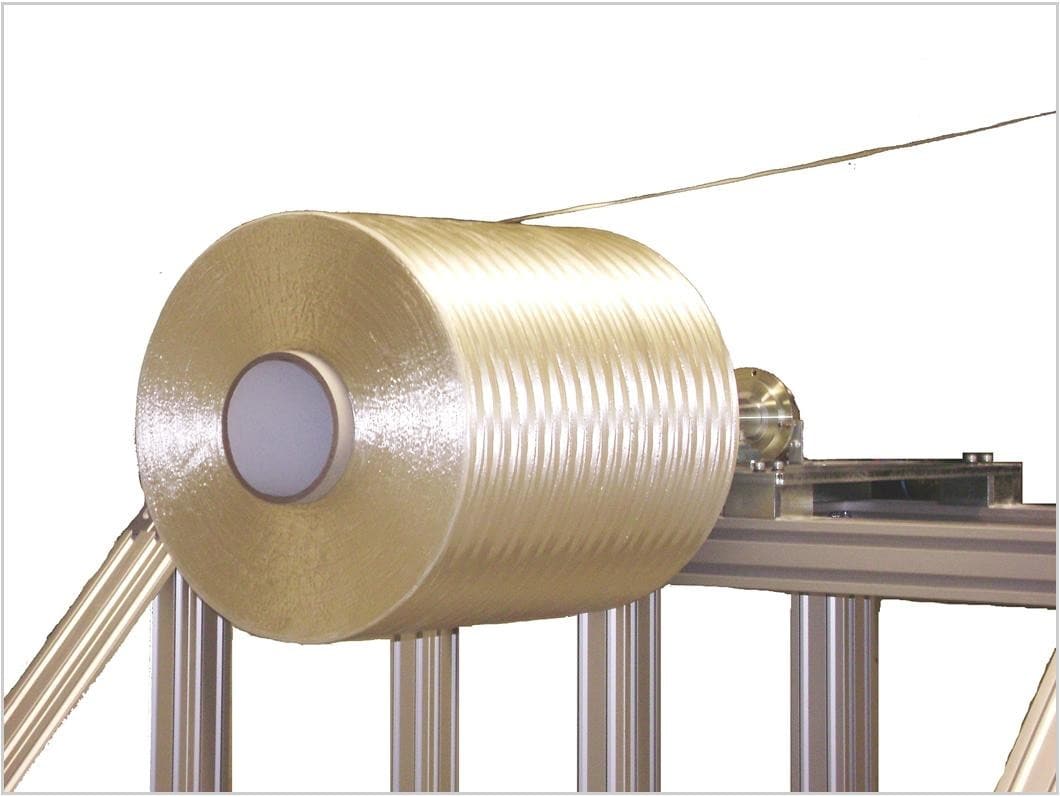

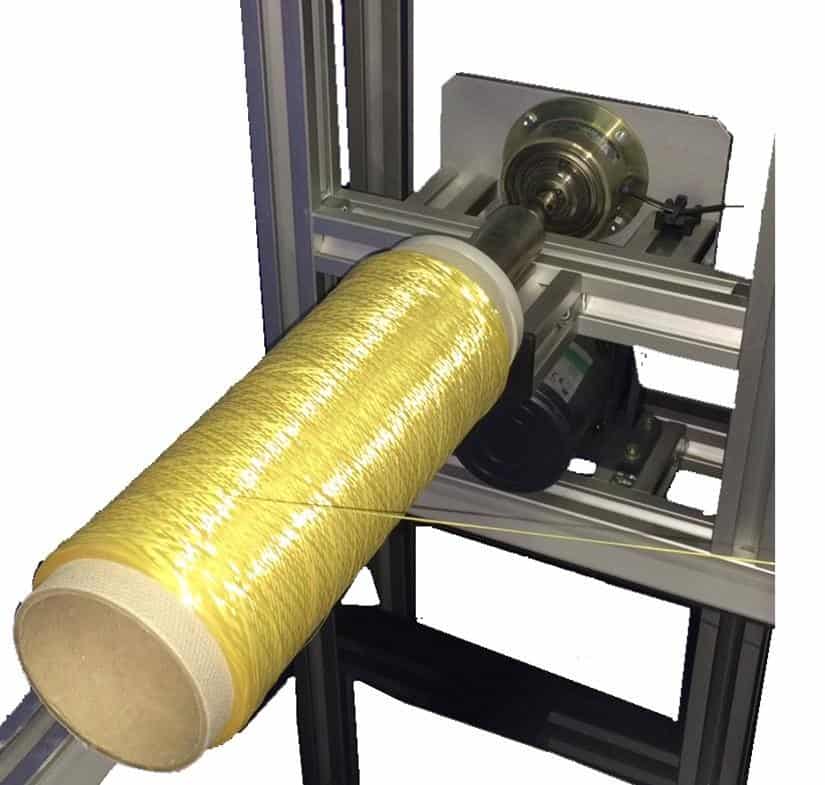

For unwinding type pay-off, Pre-preg, Tow-preg, Pultrusion, UD tape process, Lab Systems, Tow spreading lines, Carbon fiber (PAN and pitch), aramid fibers, glass fibers (on cores), optical fibers, and monofilaments.

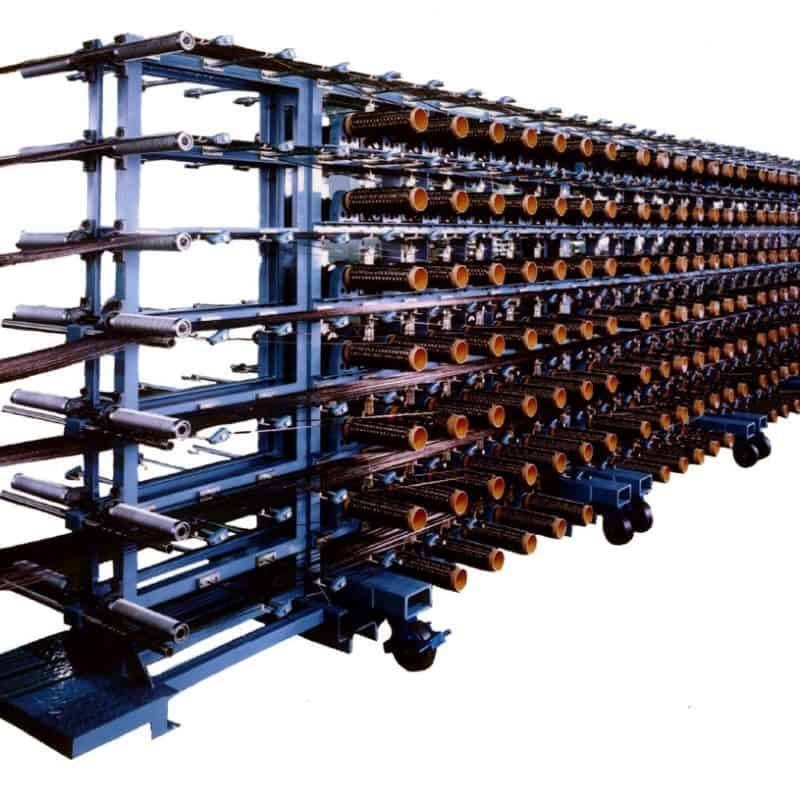

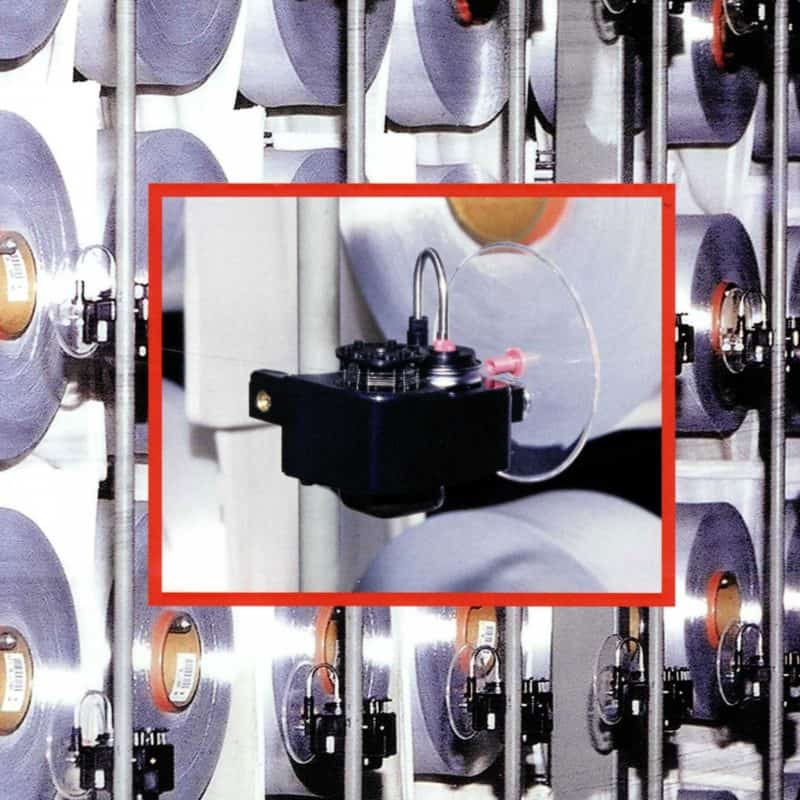

This model is based upon the same principles as the ST series, but aimed at low cost / large scale creels. Common applications for this creel are large scale (over 800 positions) creels for weaving, multi-axial machines...etc.

Diameter Measuring Tension Creel System features unwinding type electrical tension control, custom designed frame structures ideal for low cost, large scale electrical tension creel systems.

These units feedback type closed loop control creels, and are customized to user requirements. Convenient for laboratory, R&D and pilot line scale setups, also for full production lines. Standard type is a let-off type creel, but in-line type creels can be supplied also.

Precursor Tensioning Creel System features unwinding type electrical tension control with custom designed frame structures and fiber routing to accommodate customer requirements.

Bi-directional tension control for applications requiring let-off and take-back. Includes data monitoring/logging software for tension available

In-Line Tensioning for High Tension - for fibers requiring in-line tensioning, the ideal solution for tensioning pull glass fibers or over aramid fibers which require tensions over 50 grams.

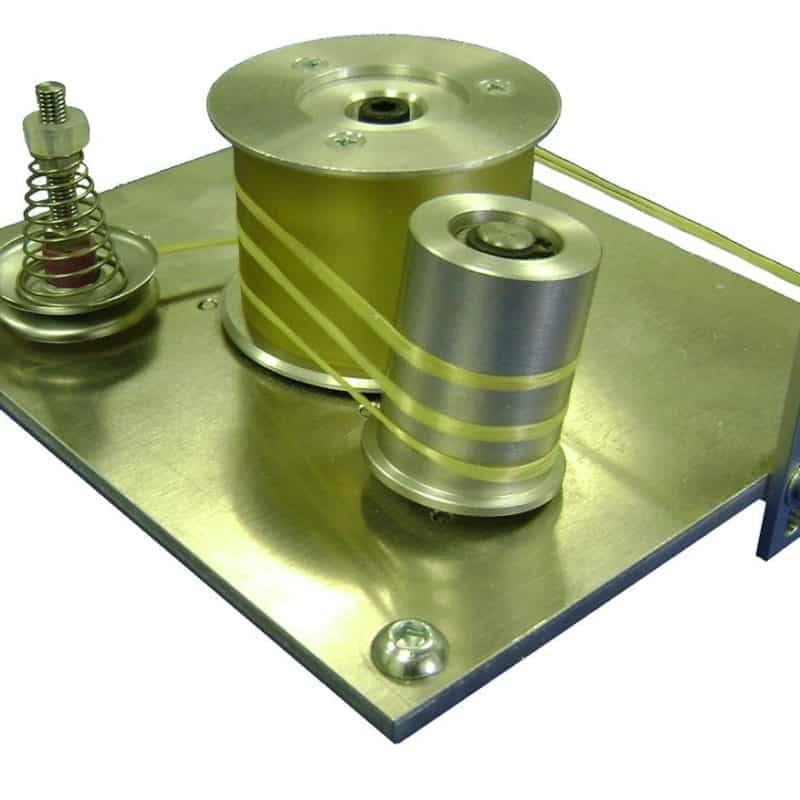

The TOP1000 is a magnetic type tension device designed especially for fiberglass tensioning on beam warping creels. The unit can also be used for various applications requiring fiber tension control.

- On board microprocessor corrects tension deviation within +/- 1 gram

- Unique tension wheel eliminates yarn damage and filament breakage

- Non Contact Hysteresis Brake

- Tension conol unit conols 20 tension devices

- Simple operation

- Programmable at 1 gram intervals

- Because of no secular change, consistent high accuracy is maintained even after long use

- Internal Gearing Type Hysteresis Brake Mechanism offers small moment of inertia and higher RPM operation

- No joint on the Hysteresis material for smooth emanated torque

- Microcomputer equipped Controller

- Corrects each unit deviation by microcomputer

- Simultaneous remote tension setting for all positions

- Parallel wiring connections saves on wiring material

- Yarn Break Detection Function (optional)

- Yarn Length Measuring Function (optional)