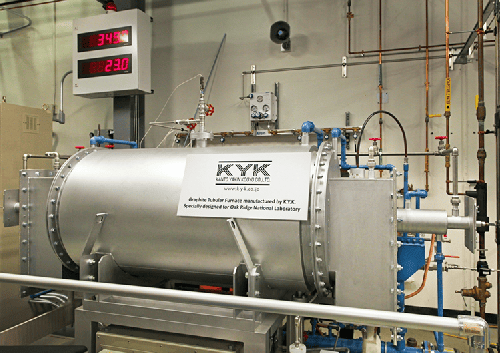

Tube type carbonization and graphitization furnaces are convenient for lab scale and pilot line applications. These small scale furnaces can be designed for single tow carbonization to larger scale tow band carbonization.

This is a compact tabletop winder, convenient for simple take up winding. The unit is equipped with an adjustable traverse length. Suitable for carbon fibers and other high performance fibers. The winder is available in the following configurations: - Constant RPM winder - Constant speed winder - Constant tension winder

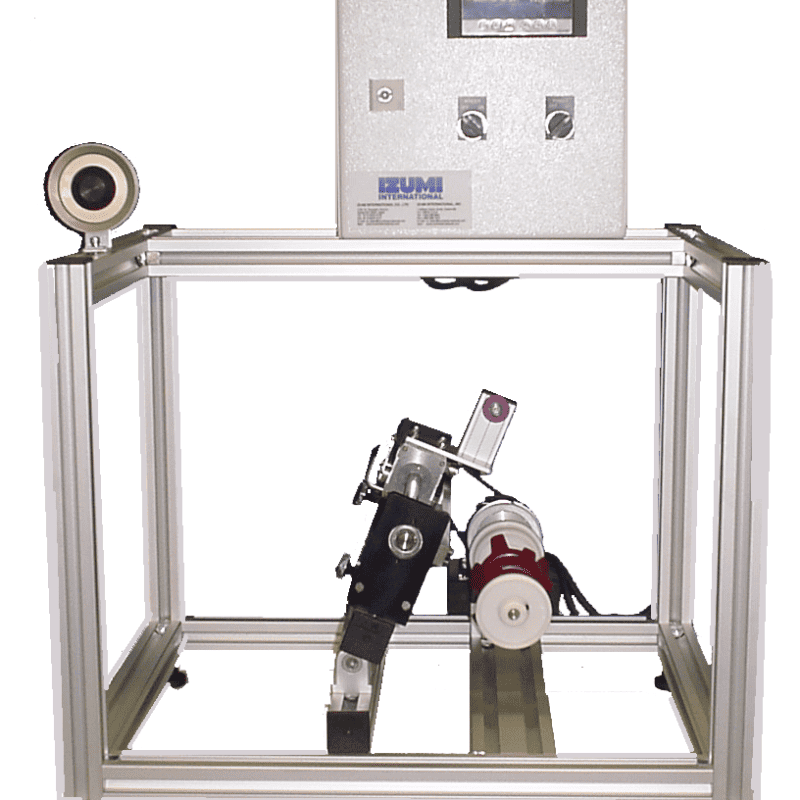

Servo driven tensioning rollers can be custom configured to drive and stretch fibers. These units have configurable parameters such as roller width, fiber speed, and stretch ratio to optimize research and development of different fibers. Control systems and operator interfaces are programmed and developed for each process requirement.

Custom built mechanical spreaders are available with adjustable spreading widths. Various roller finishes are available to match up to different fiber requirements and spreading requirements. When mechanical spreading means are not sufficient, the air spreading systems should be used.

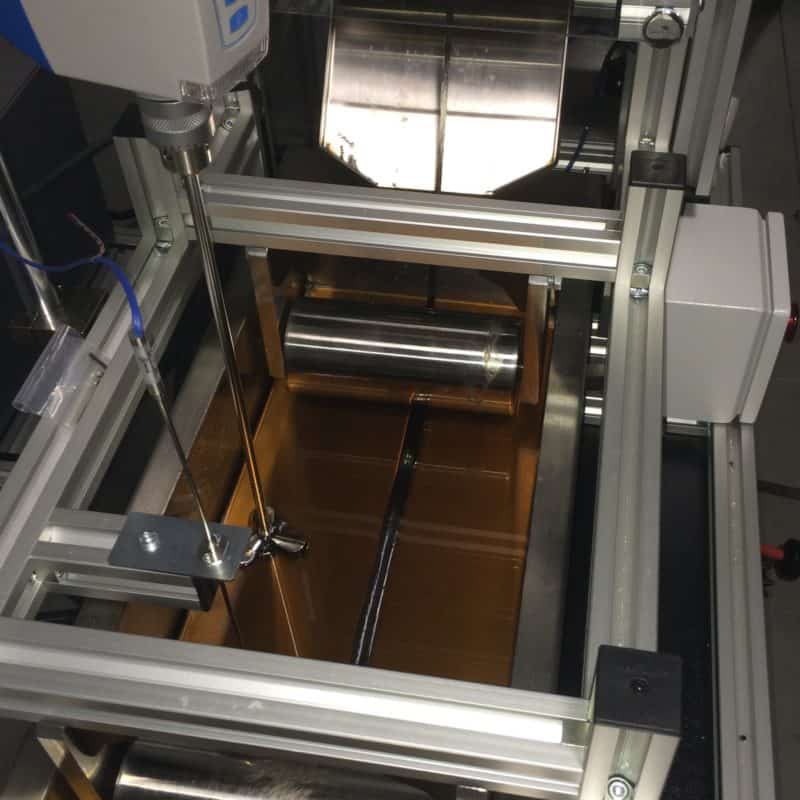

- Lab scale sizing system for carbon fiber and other high performance fibers

- Convenient for testing different sizing materials on different types of fibers

- Can be configured for single tows up to 20 tows

- Most parameters on the machine are adjustable, making the unit versatile for laboratory use

This weft feeder is for weft insertion of flat-type material such as tape yarn, prepreg tape, carbon fiber etc., without twisting the fiber. The unit is an alternative for conventional accumulators, or applications simply taking the fiber off the end of the package, which will twist the yarn during the process.

Off Loom Take Up for winding fabric from weaving machine to create large diameter rolls

The DTH tension sensor measures the tension of fibers or sheet materials with high levels of accuracy. Each unit’s microchip corrects mechanical deviations between units, giving your production line a cost-effective method of tension measurement with no calibration required. This tension sensor includes software (optional) that works with your existing PC to track and record data in an easy-to-read real time graph and also to Excel spreadsheet format. Multiple models are available to handle different fiber/web widths, tension ranges, and methods of data transmission.

This is the standard range DTH sensor with ranges from 50 grams up to 3000 grams. Roller widths range from 2.5mm up to 42mm.

This is the high range DTL sensor with ranges from 5000 grams up to 20000 grams. Roller widths range from 22mm up to 62mm.

This is the wide roller DTW sensor with ranges from 1000 grams up to 5000 grams. Roller widths range from 210mm to 610mm.

This is a customizable web tension roller and load cell combination suitable for up to 200kg of tension. Roller widths can be up to 3000mm wide.