6-Axis Dispensing Robot Systems

March 23, 2022

Industrial Control Panels

December 12, 2023Carbon Fiber Thermoplastic Tape Extrusion Line

Request Info & PricingGet a Quote

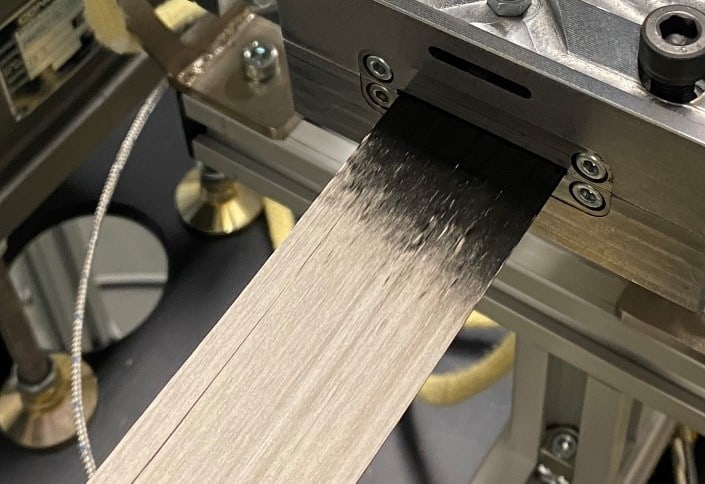

Lab scale carbon fiber reinforced thermoplastic extrusion line.

The systems can be configured to work with a variety of thermoplastic materials.

Tapes of up to 200mm width can be output with the system.

Basic Specifications

Configuration: Tabletop system or floor standing system

Tape widths: Up to 200mm wide tape

Input bobbins: Flexible depending on fiber used and tape specifications

Enclosure / Exhaust

Full polycarbonate enclosures can be provided to keep carbon fiber fly contained or to keep exhaust gasses contained. Exhaust vacuum systems available upon request.

Let off creel

Select from mechanical or electrical creels depending on fiber type and resin requirements.

Number of positions can be determined by customer tape requirements.

Handles a variety of fibers: compatible with carbon fibers, glass fibers, aramid fibers.

Compatible with 3K to 50K carbon fibers.

Fiber de-sizing and fiber sizing systems

Optional fiber de-sizing systems for use when sizing on the fiber is not required.

Fiber sizing systems prior to entry of extrusion die when applying specific sizing compatible with thermoplastic resins.

The sizing systems are equipped with drying system after sizing is applied.

Spreading

Spreading system to spread fibers before entering the extrusion die.

Choose from static spreading bars, free rolling spreading bars, high speed rotating

spreader bars depending on fiber type, FAW, tape thickness requirements.

Extruder

Tabletop extruder with AC vector controlled drive.

Equipped with multi-zone heater with individual temperature control.

Stainless steel feed hopper for resin pellets.

Water cooling circuit equipped with flow sensors.

Extrusion Die

Fiber entry comb to regulate fiber band width at entry of die.

Fiber spreader and resin impregnation features are built into the internal pathway of the die to maximize thermoplastic impregnation of the fiber.

Incorporates adjustable exit die jaws to adjust exit thickness of tape.

Die temperature control by dedicated temperature controllers.

Cooling

Air cooling or water cooling systems can be provided based on line speed requirements and tape requirements.

Tape Drive Roller

Multi-roller friction drive roller system to pull tape at constant speed.

AC motor or servo motor depending on required speed accuracy.

Winder

Take up winder collects tape as fed by tape drive roller.

Reel winders as well as bobbin traverse winders can be provided.