BDT-X Bi-Directional Creels

March 23, 2022

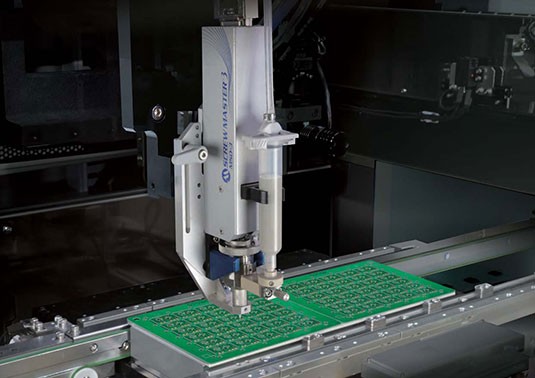

Screw Master 3 Dispenser

March 23, 2022SuperΣCM3 Pneumatic Dispenser

Request Info & PricingGet a Quote

Prevent waste and errors with the high-precision Musashi SuperΣCM3 pneumatic dispenser. Ideal for ultra-fine dot and line dispensing of adhesives, silicone resin, lubricants, epoxy, and more, the SuperΣCM3 offers ultimate pneumatic dispensing stability with the following features:

- Vacuum control system to stop drips and aeration

- Automatic correction of pressure head variation to improve consistency

- Accurate detection of low fluid levels in syringe to prevent empty shots and wasted fluid

These innovations reduce the NG (reject) rate by 70%.

Dispensing Method

– Pneumatic (Air Pulse)

Discharge Pressure Setting

– Microcomputer control electro/pneumatic method

Dispense Mode

– Timed mode / Manual mode

Vacuum Pressure Set Range

– -0.020-0 MPa

Main Function

– Water head difference automatic compensation, dripping automatic prevention, automatic residual quantity warning, α revision, δ revision

– Vacuum pressure revision, residual quantity indication revision, dispense counter, stopwatch

– Japanese-English indication reshuffling

– Supply pressure error, exhaust error, vacuum pressure error

– Solenoid valve error, solenoid valve warning

Number of Channels

– 100 CH

RS232C Serial Communication

– Possibility

Input Signal

– We pre-set dispense, channel reshuffling, dispense mode reshuffling, channel, channel designation, channel step

Output Signal

– While is completed, and dispense cycles among dispense lady, dispense; solenoid valve alarm, error, under residual quantity warning, electricity

Rating Power Supply and Frequency

– AC100-240 V 50/60 Hz

Power Consumption

– 30W

Conformity Standard

– CE marking (low voltage order, EMC order) EU RoHS

External diameter dimensions W*D*H

– W300 X D300 X H100 mm

Weight

– 5.8 kg