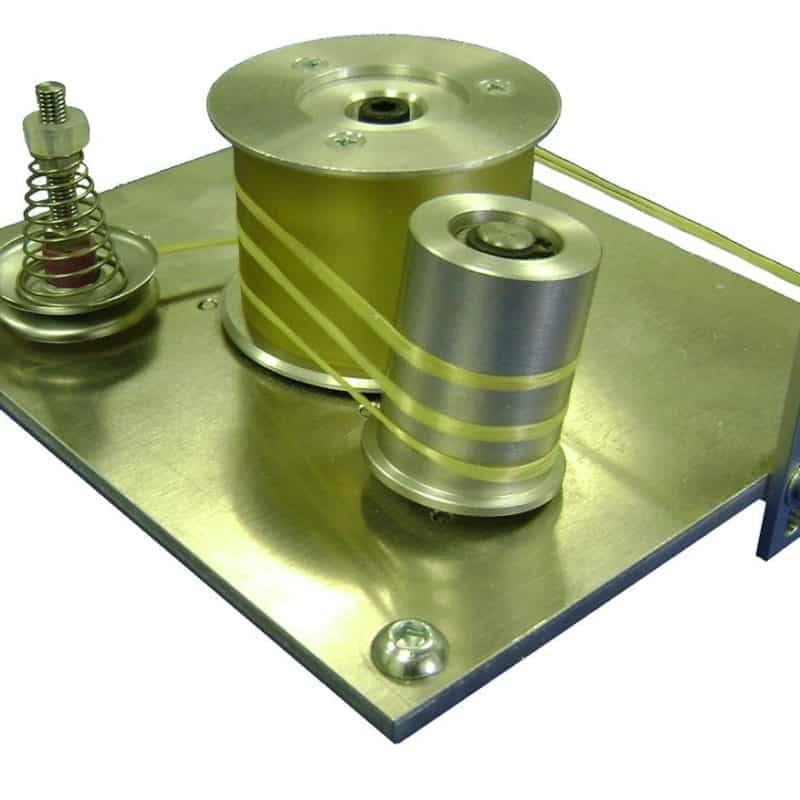

In-Line Tensioning for High Tension - for fibers requiring in-line tensioning, the ideal solution for tensioning pull glass fibers or over aramid fibers which require tensions over 50 grams.

TAKANO Bi-stable Rotary solenoids apply cylindrical permanent magnet for rotor. Rotary motion is performed by attraction and dis-attraction of magnetic pole generated by rotor and yoke. TAKANO Solenoid makes direct rotary motion without any axial movement, which contributes to the durability of this product. It differs from the conventional rotary solenoid which generate mechanical axial motion and change the axial motion to rotary motion.

The Delta brushless DC motor (BLDCM) is a synchronous electric motor with permanent magnets. It is powered by DC and incorporates an electronically controlled commutation system, instead of a mechanical commutation system based on brushes. Using an electronically controlled commutation system offers several advantages compared to other motor structures. There is less mechanical/electrical noise, lower temperature, no brush dust, and lower rotor losses. All this adds up to higher efficiency, performance, and energy savings compared to a traditional motor.

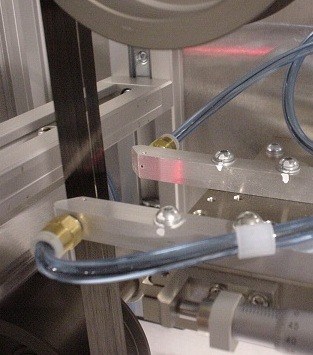

For analysis of carbon fiber characteristics and carbon fiber quality control. Analysis of fiber tow width, filament breakage, fiber tension, etc. For laboratory / pilot line use (CFA-F), as well as for monitoring fiber on carbon fiber production lines (CFA-Lite). Simple data acquisition (USB type media or SD card) or on-line data acquisition via PC supplied for monitoring and data logging.

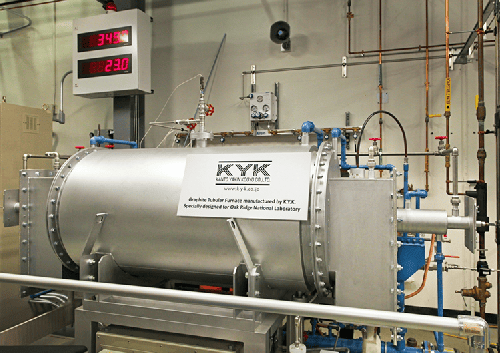

Tube type carbonization and graphitization furnaces are convenient for lab scale and pilot line applications. These small scale furnaces can be designed for single tow carbonization to larger scale tow band carbonization.

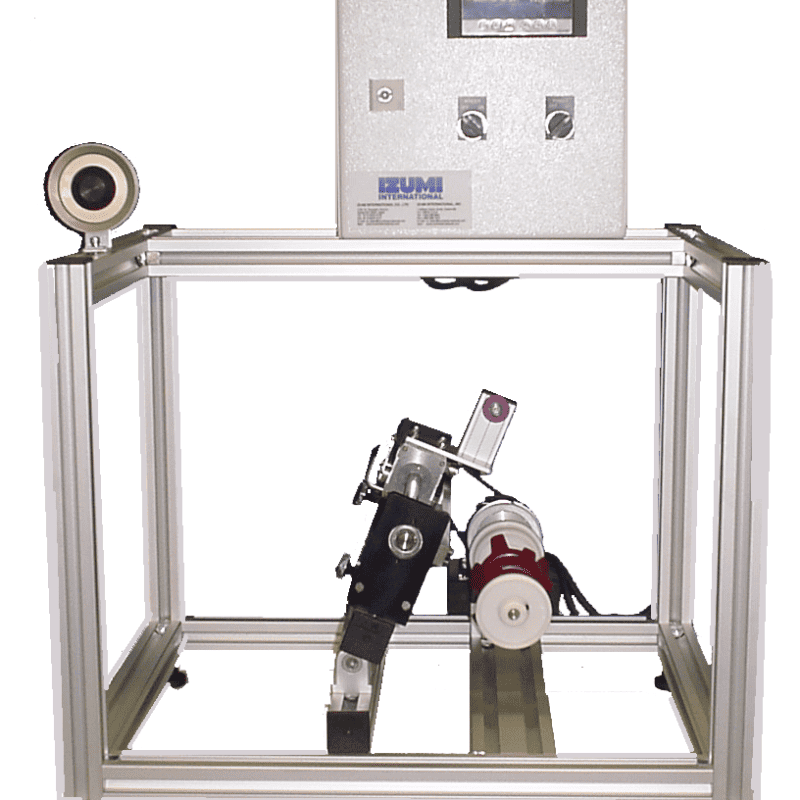

This is a compact tabletop winder, convenient for simple take up winding. The unit is equipped with an adjustable traverse length. Suitable for carbon fibers and other high performance fibers. The winder is available in the following configurations: - Constant RPM winder - Constant speed winder - Constant tension winder

Servo driven tensioning rollers can be custom configured to drive and stretch fibers. These units have configurable parameters such as roller width, fiber speed, and stretch ratio to optimize research and development of different fibers. Control systems and operator interfaces are programmed and developed for each process requirement.

Custom built mechanical spreaders are available with adjustable spreading widths. Various roller finishes are available to match up to different fiber requirements and spreading requirements. When mechanical spreading means are not sufficient, the air spreading systems should be used.

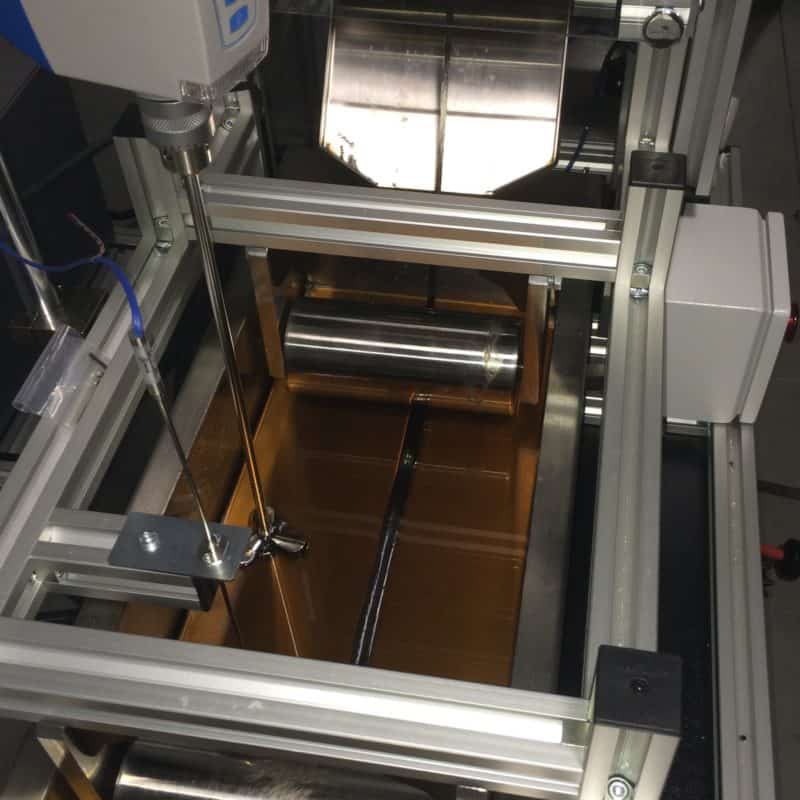

- Lab scale sizing system for carbon fiber and other high performance fibers

- Convenient for testing different sizing materials on different types of fibers

- Can be configured for single tows up to 20 tows

- Most parameters on the machine are adjustable, making the unit versatile for laboratory use

This weft feeder is for weft insertion of flat-type material such as tape yarn, prepreg tape, carbon fiber etc., without twisting the fiber. The unit is an alternative for conventional accumulators, or applications simply taking the fiber off the end of the package, which will twist the yarn during the process.

The Cross Roller Ring is a roller bearing with high rotation accuracy capable of bearing loads in every direction. Because it has orthogonally arranged cylindrical rollers, it can bear loads in every direction.

Off Loom Take Up for winding fabric from weaving machine to create large diameter rolls